|

|

Home > Water > Water conditining operations

Water conditioning operations

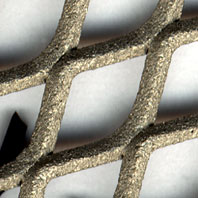

Among the more up-to-date water conditioning systems there are those by means of electrolytic oxidation both with aluminum and iron disposable anodes, as well as with stable dimension anodes of titanium coated with iridium, ruthenium, platinum, etc. oxides. We have portable units to make on-the-spot water conditioning tests with both types of anodes, and industrial pilot plants can be realized to evaluate exactly the performance of the treatment and to optimize the project for the final plant.